| |

|

Coating System for pipelines-Inner Layer

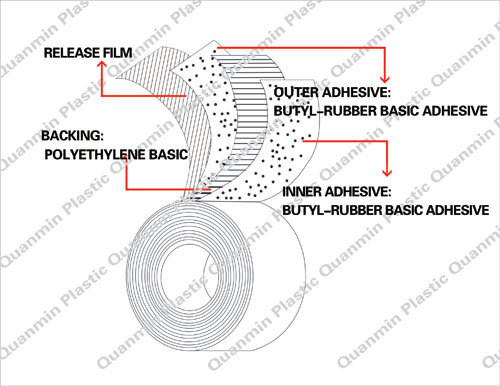

T400 3 Ply tape is a three-ply cold applied tape with polyethylene backing and butyl rubber adhesive layers on both sides. It is also used as inner-layer tape. It shall be applied by hand or with a wrapping machine The 3 Ply tape shall be applied after the Liquid adhesive and before the outer-layer tape by hand or with a wrapping machine.

Features:

Excellent bonding between adhesive and carrier film via co-extruded intermediate layer.

Mechanically highly resistant tape system.

Practically impermeable to water vapour and oxygen.

Resistant to soil bacterial and soil electrolyte.

The innerwrap completely self-amalgamates in the overlap areas, forming a sleeve-type coating which is impermeable to water vapour and oxygen.

Due to the special composition the tape show good resistance to elevated temperatures. The tape is further highly conformable to any uneven surface structure.

A Total Coating System with:

High adhesion and shear resistance

Resistance to corrosion disbondment

High electrical resistance

High dielectric strength

High corrosion protection for steel substrates

Text Data sheet:

|

Phisical Properties

|

Test Method

|

T476-30

|

T481-32

|

|

Metric

|

Englishi

|

Metric

|

Englishi

|

|

Total Thickness

|

ASTM D 1000

|

0.770mm

|

30 mils

|

0.830mm

|

32 mils

|

|

Adhesive Thickness(External)

|

ASTM D 1000

|

0.250mm

|

10 mils

|

0.160mm

|

6 mils

|

|

Adhesive Thickness(Internal)

|

ASTM D 1000

|

0.260mm

|

10 mils

|

0.360mm

|

14 mils

|

|

Backing Thickness

|

ASTM D 1000

|

0.260mm

|

10 mils

|

0.310mm

|

12 mils

|

|

Tensile Strenght

|

DIN 30672/1

|

64.5 N/cm

|

36.3 lbs/in

|

72 N/cm

|

41.2 lbs/in

|

|

Elongation

|

DIN 30672/1

|

510%

|

510%

|

570%

|

570%

|

|

Shear Resistance

|

DIN 30672/1

|

0.054 N/mm2

|

125 oz/sqin

|

0.060 N/mm2

|

139 oz/sqin

|

|

Peel strength to Primed Steel at (180 º)

|

|

At 23 ºC

|

DIN 30672/1

|

18 N/cm

|

165 oz/in

|

20 N/cm

|

183 oz/in

|

|

At 50 ºC

|

DIN 30672/1

|

2.4 N/cm

|

22 oz/in

|

2.7 N/cm

|

25 oz/in

|

|

Peel strength outer layer to inner layer(180 º)

|

|

At 23 ºC

|

DIN 30672/1

|

36 N/cm

|

329 oz/in

|

45 N/cm

|

411 oz/in

|

|

At 50 ºC

|

DIN 30672/1

|

4.8 N/cm

|

44 oz/in

|

6.0 N/cm

|

55 oz/in

|

|

Water Absorption

|

ASTM D 570

|

0.06%

|

0.06%

|

0.05%

|

0.05%

|

|

Water Vapor Transmission Rate (24h)

|

ASTM E 96

|

0.13g/m2·24h

|

0.083g/100sq in/24h

|

0.075g/m2·24h

|

0.005g/100sq in/24h

|

|

Insulation Resistance

|

ASTM D 257

|

108 Mohm

|

10E 8 Mohm

|

1010 Mohm

|

10 E10Mohm

|

|

Dielectric Strenght

|

ASTM D 1000

|

41 KV/mm

|

1041volts/mil

|

43 KV/mm

|

1092volts/mil

|

|

Impact Resistance

|

DIN 30672/1

|

15.3 N·m

|

15.3 Joules

|

15.5 N·m

|

15.5 Joules

|

|

Color

|

Black

|

|

Tape width in inches

|

50mm(2″),101mm(4″),152mm(6″),228mm(9″),305mm(12″),457mm(18″),

610mm(24″),750mm(29.5″)

|

|

Tape roll length in feet

|

15m(50ft),25m(82ft),30m(98ft),50m(164ft),61m(200ft),100m(328ft),122m(400ft),183m(600ft),244m(800ft)

|

|

Core size

|

38mm(1.5″)、76mm(3″) core of paper or hard plastic

|

|

Application Temperature

|

-34 ºC to +85 ºC ( -29 ºF to 185 ºF )

|

|

Operating Temperature

|

+85 ºC ( 185 ºF )

|

|

Phisical Properties

|

Test Method

|

T4100-40

|

T4110-43

|

|

Metric

|

Englishi

|

Metric

|

Englishi

|

|

Total Thickness

|

ASTM D 1000

|

1.01mm

|

40 mils

|

1.10mm

|

43.5 mils

|

|

Adhesive Thickness(External)

|

ASTM D 1000

|

0.25mm

|

10 mils

|

0.41mm

|

16 mils

|

|

Adhesive Thickness(Internal)

|

ASTM D 1000

|

0.50mm

|

20 mils

|

0.50mm

|

20 mils

|

|

Backing Thickness

|

ASTM D 1000

|

0.26mm

|

10 mils

|

0.19mm

|

7.5 mils

|

|

Tensile Strenght

|

DIN 30672/1

|

71 N/cm

|

40.5 lbs/in

|

70 N/cm

|

40.0 lbs/in

|

|

Elongation

|

DIN 30672/1

|

550%

|

550%

|

530%

|

530%

|

|

Shear Resistance

|

DIN 30672/1

|

0.060 N/mm2

|

139 oz/sqin

|

0.060 N/mm2

|

139 oz/sqin

|

|

Peel strength to Primed Steel at (180 º)

|

|

At 23 ºC

|

DIN 30672/1

|

28 N/cm

|

256 oz/in

|

28 N/cm

|

256 oz/in

|

|

At 50 ºC

|

DIN 30672/1

|

3.7 N/cm

|

33.8 oz/in

|

3.7 N/cm

|

33.8 oz/in

|

|

Peel strength outer layer to inner layer(180 º)

|

|

At 23 ºC

|

DIN 30672/1

|

50 N/cm

|

457 oz/in

|

55 N/cm

|

503 oz/in

|

|

At 50 ºC

|

DIN 30672/1

|

6.6 N/cm

|

60.3 oz/in

|

8.5 N/cm

|

77.7 oz/in

|

|

Water Absorption

|

ASTM D 570

|

0.05%

|

0.05%

|

0.05%

|

0.05%

|

|

Water Vapor Transmission Rate (24h)

|

ASTM E 96

|

0.075 g/m2·24h

|

0.05 g/m2·24h

|

0.075 g/m2·24h

|

0.05 g/m2·24h

|

|

Insulation Resistance

|

ASTM D 257

|

1012Mohm

|

10 E12 Mohm

|

1014Mohm

|

10 E14 Mohm

|

|

Dielectric Strenght

|

ASTM D 1000

|

43 KV/mm

|

1092 volts/mil

|

45 KV/mm

|

1143 volts/mil

|

|

Impact Resistance

|

DIN 30672/1

|

15.3 N·m

|

15.3 Joules

|

15.5 N·m

|

15.5 Joules

|

|

Color

|

Black

|

|

Tape width in inches

|

50mm(2″),101mm(4″),152mm(6″),228mm(9″),305mm(12″),457mm(18″),

610mm(24″),750mm(29.5″)

|

|

Tape roll length in feet

|

15m(50ft),25m(82ft),30m(98ft),50m(164ft),61m(200ft),100m(328ft),122m(400ft),183m(600ft),244m(800ft)

|

|

Core size

|

38mm(1.5″)、76mm(3″) core of paper or hard plastic

|

|

Application Temperature

|

-34 ºC to +85 ºC ( -29 ºF to 185 ºF )

|

|

Operating Temperature

|

+85 ºC ( 185 ºF )

|

Structure:

|