| |

|

Coating System for pipelines and Waterproofing works against outdoor bad weathers PP Woven fiber cloth backing supply super stronger tapes. Pipelines protection for Weld joints, Bends, Fittings, pipe lengths, Pipe rehab and repair, Bare pipe length.

PP fiber anticorrosive adhesive tape is a novelty environmental protection type anticorrosive product without pollution and harm, which represents the internationally and nationally highest level of cold winded anticorrosive adhesive tape entitled Crown of Corrosion Protection. This product can be widely used for outer corrosion protection and repair in water supply & drain, oil and gas, coal gas transmission steel pipelines and buried steel tanks in petroleum, natural gas, chemical industry, municipal construction. This product is recommended by Ministry of Construction and State Environmental Protection Administration People’s Republic Of China as a product in lieu of pitch fiber –glass and epoxy coal pitch. This product has such features as easy construction, impact resistance, anti-aging, stretch proofing, anti- ultraviolet radiation, high cohesive strength, etc.

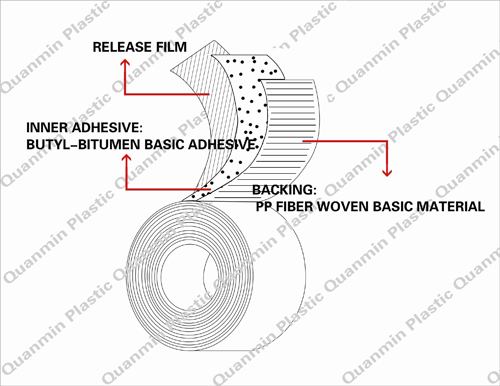

This product consists of modified PP woven fabrics as base material and butyl rubber modified asphalt as anti-corrosive adhesive layer. The base material is a fiber structure to effectively resist creep fracture caused by soil stress, and has anti-corrosive life as long as above fifty years obtained from ageing test. All the test indices of this product exceed the typical values of SY/T0414-98, and meet ANSI/AWWAC209-00 and NACEMR0274-95, so this product is the optimal and economical choice of cold anti-corrosive construction adhesive tapes for pipeline.

Use method:

(1) Steel pipe surface preparation: Remove rust, welding slag, burr, oil and dirt and keep clean and dry. Manual rust removal shall reach Class St3, mechanical rust removal shall reach Class Sa2 and meet SYJ4007-86.

(2) Primer application: Select specialized primer and keep it away from a fire. Stir it well and apply it evenly with a clean brush or roller or in other mechanical ways. Primer consumption: 12㎡/L (Manual painting) and 20㎡/L (mechanical painting)

(3) Do not apply the adhesive tape until the primer surface is dry (typically after 5 to 10 min).

(4) Underground installation and backfill: Do not install the pipeline until it passes the quality check.

Structure:

Test Data sheet

|

Physical Properties

|

Test Method

|

T760

|

T780

|

|

Total Thickness

|

English

|

|

45mils

|

50mils

|

55mils

|

60mils

|

65mils

|

|

Metric

|

ASTM D 1000

|

1.15mm

|

1.27mm

|

1.40mm

|

1.50mm

|

1.65mm

|

|

Adhesive Thickness

|

ASTM D 1000

|

0.85mm

|

0.97mm

|

1.10mm

|

0.90mm

|

1.05mm

|

|

Backing Thickness

|

ASTM D 1000

|

0.30+0.05mm

|

0.60+0.05mm

|

|

Tensile Strength

|

ASTM D 1000

|

>600 N/cm (342.6 lbs/in)

|

>800 N/cm (456.8 lbs/in)

|

|

Peel strength to Primed Steel at

|

|

At 23 ºC

|

ASTM D 1000

|

>80 N/cm

|

( >731 oz/in )

|

|

At 50 ºC

|

ASTM D 1000

|

>10.5 N/cm

|

( >96 oz/in )

|

|

Adhesion to backing at

|

ASTM D 1000

|

>65 N/cm

|

( >594 oz/in )

|

|

Cathodic Disbondment

|

ASTM G 8

|

8.0mm

|

( 0.315 in radius )

|

|

Water Absorption Rate

|

ASTM D 570

|

<0.10%

|

( <0.10% )

|

|

Water Vapor Transmission Rate

|

ASTM F 1249

|

<0.15 g/m2·24h

|

( <0.01g/100sqin/24h )

|

|

Insulation Resistance

|

ASTM D 257

|

2.5×1012 ohm·cm

|

( 2.5 by 10E 12 Mohm )

|

|

Dielectric Strength

|

ASTM D 149

|

25 KV

|

( 25 KV )

|

|

Impact Resistance

|

ASTM G 14

|

23 N·m

|

( 204 in·lbs )

|

|

Color

|

Black

|

|

Tape width in inches

|

50mm(2"),101mm(4"),152mm(6"),228mm(9"),305mm(12"),457mm(18"),

610mm(24"),750mm(29.5") ,800mm(31.5"),1000mm(39")

|

|

Tape roll length in feet

|

15m(50ft),25m(82ft),30m(98ft),50m(164ft),61m(200ft),100m(328ft),122m(400ft),

|

|

Core size

|

38mm(1.5"),76mm(3") core of paper or hard plastic

|

|

Application Temperature

|

-34 ºC to +120 ºC

|

( -29 ºF to 120 ºF )

|

|

Operating Temperature

|

+120 ºC

|

( 248 ºF )

|

|