| |

|

Description

Aluminum Foil Tape, Flashing Tape, Peel/Stick Roof Tape, Alu Bitumen tape, Alu waterproof tape, Sealing tape has a heavy aluminum facing together with an extra thick rubberized asphalt based adhesive system.

A cold applied self adhesive aluminum backing flashing in tape form. The product is made from substrate of aluminum foil, which has unique capability to reflect sunlight and anti-UV as well as flexibility and surface smoothness, and butyl rubber modified asphalt adhesive of high anticorrosive and adhesion. Therefore, the aluminum foil anticorrosion tape is Waterproof, anti-aging, non-curing, non-cracking, without moving and peeling for a long term, so that the anticorrosion capability is strong and the appearance is good. It has been proved that the product is excellent for anticorrosion.

Uses:

-T800 series is recommended for most types of roofs, windows and flashing problems including:

-Trailers

-RV’S

-Mobile homes

-Industrial buildings

-Roof awnings

-Truck trailers

-Chimney Flashing

-Roof to wall flashing

-Ridge Flashing

-Window frames of glass, metal, plastic

-Wood including OSB

-Clay and Cement Roof Tiles

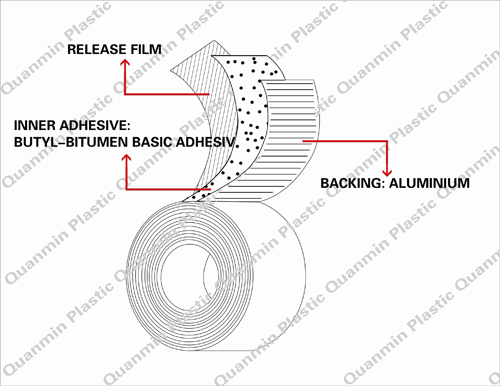

Composttion:

High melting point polymer bitumen adhesive laminated to a 50-70 micron aluminum. The adhesive surface is protected by a release coated plastics film which is discarded during use.

Features:

Easy application-Installations fast and easy—simply remove the release film and press onto the substrate.

Superior adhesion capabilities-Creates a strong bond to the substrate for long-lasting waterproofing protection.

Excellent sealing performance-The specially formulated rubberized asphalt adhesive seals around fasteners, allowing no water to penetrate and get to the substrate.

Highly conformable and flexible–Can accommodate settlement and shrinkage movement.

Long-lasting waterproofing protection-Both the aluminum surfaced polyethylene film and pure alu surface with the specially-formulated rubberized asphalt components create a water and moisture barrier that does not degrade from the effects of the environment.

Usage:

Surface treatment: clear the rust, welding spatter, burr, oil, dirt, and dry it. Class St3 should be reached for manual rust removal.

Apply the primer: an exclusive primer should be used, and the use should be away from fire source. Stir it until it is even, use clean brush, roller or other mechanical means to paint it evenly. Amount of primer to be used: for manual painting: 12/L, for mechanical painting: 20/L The winding may be performed 5-10 minutes after surface drying of primer.

Temperature for use: —5ºC--+50ºC.

Transportation and storage:

Avoid exposure to the sun and rain, and prevent freezing by heat preservation. Prevent crush and deformation. Do not be close to heat and open flame. Temperature for transportation and storage: -20ºC--+35ºC.

Storage period: 6 months

Test Data sheet

|

Physical Properties

|

Test Method

|

T850-40

|

T850-48

|

T850-55

|

T850-60

|

T850-70

|

|

Total Thickness

|

ASTM D 1000

|

1.00mm

|

1.20mm

|

1.40mm

|

1.50mm

|

1.70mm

|

|

Adhesive Thickness

|

ASTM 1000

|

0.90mm

|

1.15mm

|

1.35mm

|

1.45mm

|

1.65mm

|

|

Backing Thickness

|

ASTM D 1000

|

≥0.05mm

|

|

Elongation of adhesive

|

ASTM D 1000

|

>1200%

|

( >1200% )

|

|

Peel strength of substrate

|

ASTM D 1000

|

>65 N/cm

|

( >594 oz/in )

|

|

Peel strength to primed steel

|

ASTM D 1000

|

>80 N/cm

|

( >731 oz/in )

|

|

Peel strength of the cement surface of the primer

|

ASTM D 1000

|

> 55N/cm

|

( >503 oz/in )

|

|

Water Absorption Rate

|

ASTM D 570

|

<0.10%

|

( <0.10% )

|

|

Water Vapor Transmission Rate

|

ASTM F 1249

|

<0.1 g/m2·24h

|

( <0.0064g/100sqin/24h )

|

|

Insulation Resistance

|

ASTM D 257

|

2.0×1015 ohm.cm

|

( 2.0 by 10 E 15 Mohm )

|

|

Dielectric Strength

|

ASTM D 149

|

25KV

|

( 25 KV )

|

|

Color

|

Silvery white

|

|

Tape width in inches

|

50mm(2"),101mm(4"),152mm(6"),228mm(9"),305mm(12"),457mm(18"),

610mm(24"),750mm(29.5"),800mm(31.5"),1000mm(39")

|

|

Tape roll length in feet

|

15m(50ft),25m(82ft),30m(98ft),50m(164ft),61m(200ft),100m(328ft),122m(400ft)

|

|

Core size

|

38mm(1.5")、76mm(3") core of paper or hard plastic

|

Structure:

|