|

|

|

|

|

|

|

|

|

|

|

Cầu chì Bussmann

|

|

|

|

|

|

|

|

|

|

THIẾT BỊ CƠ KHÍ

|

|

|

|

|

|

|

|

|

|

Giá vàng

|

|

|

|

|

|

|

|

SẢN PHẨM CHÍNH

|

|

|

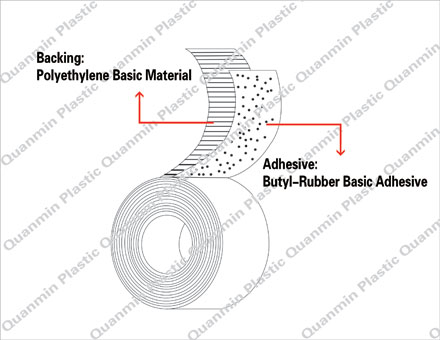

PE Inner Anti-corrosioin Tapes (T200)

|

|

|

|

| |

|

Coating System for pipelines-Outer Layer:

T200 series are 2-Ply polyethylene (PE) anticorrosive adhesive tapes. It is Cold wrap tape coating system for Corrosion Protection of Water, Oil and Gas Pipelines. The outer-layer tape backing shall be compounded so that it will be resistance to outdoor weathering.

Features:

Excellent adhesion to inner-layer tape and self

Resistant to UV

Can be applied over a wide temperature range

Good conformability and consistent uniform thickness

Easily applied with no special equipment

Compatible with common pipe coatings

Excellent resistance to cathodic disbonding

Meets ASTM D 1000 Standard

Cold applied

Technical Data Sheet

|

Type

|

T238-15

|

T250-20

|

T265-25

|

T275-30

|

|

Total thickness

|

0.381mm

|

0.510mm

|

0.650mm

|

0.770mm

|

|

Polyethylene Film

|

0.251mm

|

0.380mm

|

0.510mm

|

0.620mm

|

|

Butyl Rubber Adhesive

|

0.130mm

|

0.130mm

|

0.140mm

|

0.150mm

|

|

Elongation at break

|

550%

|

587%

|

605%

|

620%

|

|

Tensile Strength

|

56.3 N/cm

|

68.8 N/cm

|

72.2 N/cm

|

75.0 N/cm

|

|

Yield Strength

|

35.2 N/cm

|

43.0 N/cm

|

45.0 N/cm

|

50.0 N/cm

|

|

Adhesion to backing at

|

5.0 N/cm

|

5.0 N/cm

|

5.0 N/cm

|

5.1 N/cm

|

|

Dielectric Strength

|

34.0 KV

|

36.0 KV

|

38.5KV

|

40.0 KV

|

|

Impact resistance

|

≥5.5 N•m

|

|

Cathodic Disbondment

|

6.4mm

|

|

Volume Resistivity

|

≥2.3X1015 ohm.m

|

|

Water Vapor Transmission r ate

|

≤0.08 g/m2/24h

|

|

Water Absorption Rate

|

≤0.05%

|

|

Application Temperature, Max Serve Temperature

|

-34 ºC to +85 ºC, +85 ºC

|

|

Color

|

White ,Black, yellow or other

|

|

Available Roll Size(width * length)

|

50 to 750mm X 15 to 240 m

|

Test Data Sheet:

|

Physical Properties

|

Test Method

|

Typical Value

|

|

English

|

Metric

|

|

Total thickness

|

ASTM D 1000

|

25 mils

|

0.640mm

|

|

Backing thickness

|

ASTM D 1000

|

20 mils

|

0.510mm

|

|

Adhesi Adhesive thickness

|

ASTM D 1000

|

5 mils

|

0.130mm

|

|

Width

|

-

|

9"

|

228mm

|

|

Length

|

-

|

800'

|

244m

|

|

Backing color

|

-

|

White

|

White

|

|

Tensile strength

|

ASTM D 1000

|

41.23 lbs/in

|

72.2N/cm

|

|

Elongation

|

ASTM D 1000

|

605%

|

605%

|

|

Adhesion to backing at

|

ASTM D 1000

|

45.7 oz/in

|

5.0N/cm

|

|

Cathodic Disbondment

|

ASTM G 8

|

0.252 in radius

|

6.4mm

|

|

Dielectric Strength

|

ASTM D 149

|

38.0 KV

|

38.0 KV

|

|

Impact resistance

|

ASTM G 14

|

50 in-lbs

|

5.5 N•m

|

|

Volume Resistivity

|

ASTM D 257

|

2.5×1015 ohm.cm

|

2.5×1015 ohm.cm

|

|

Water Absorptivity

|

ASTM D 570

|

0.05%

|

0.05%

|

|

Water Vapor Transmissioin Rate 24 h

|

ASTM F 1249

|

0.005 g/100sq in/24h

|

0.075 g/ m2.24h

|

|

Application Temperature

|

-

|

-29ºF to 185 ºF

|

-34 ºC to +85 ºC

|

|

Max Service Temperature

|

-

|

185ºF

|

+85 ºC

|

Structure:

Working Drawing:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|