|

|

|

|

|

|

|

|

|

|

|

Cầu chì Bussmann

|

|

|

|

|

|

|

|

|

|

THIẾT BỊ CƠ KHÍ

|

|

|

|

|

|

|

|

|

|

Giá vàng

|

|

|

|

|

|

|

|

SẢN PHẨM CHÍNH

|

|

|

Open Heat Shrinkable Sleeves (HSWS)

|

|

|

|

| |

|

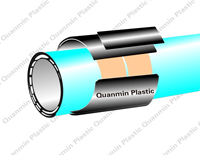

Product profile

HSWS, Two-piece, with separate closures designed for the corrosion protection. HSWS is superior performances heat shrinkable products designed for corrosion protection on field applied girth-weld joints of buried and exposed steel pipelines operating up to 80 ºC (176 ºF).

The inner layer is two-components epoxy primer which coated on steel pipe; Intermediate level is special hot melt adhesive;

Outer layer is modified radiation crossing linking polyethylene backing.

Features & Benefits:

Heat Shrinkable Sleeves provide great corrosion protection, Superior resistance to Cathodic Disbondment and excellent durability against abrasion and chemical attack. The result is effective, good performance of sealing, wide application, easy to operate and preheating temperature low (50 ºC), long term protection against corrosion.

HSWS is a wraparound sleeve with a separate closure.

Cross-linked backing provides superior abrasion, mechanical and chemical attack resistance.

High performance adhesive provides excellent resistance to Cathodic Disbondment to ensure long-term corrosion protection

Just-in-time customized lengths allow bulk rolls to be field cut to protect any pipe size

Open sleeve configuration allows the product to be applied after the pipeline has been welded and cleaned

Closure patch: 100mm, 150mm

Properties of sleeve:

|

Physical Properties

|

Typical Values

|

Unit

|

Test Method

|

|

Adhesive

|

Softening point

|

110(230)

|

ºC (ºF)

|

ASTM E28

|

|

Lap shear at 23 ºC

|

2.8(406)

|

Mpa(psi)

|

ASTM D1002

|

|

Lap shear at 60 ºC

|

0.2(29)

|

Mpa(psi)

|

ASTM D1002

|

|

Backing

|

Specific gravity

|

0.93

|

g/cm3

|

ASTM D792

|

|

Tensile strength

|

24(3480)

|

Mpa(psi)

|

ASTM D638

|

|

Elongation

|

700↑

|

%

|

ASTM D638

|

|

Hardness

|

50

|

Shore D

|

ASTM D2240

|

|

Abrasion resistance

|

35

|

mg

|

ASTM D1044

|

|

Volume resistance

|

1015

|

Ohm-cm

|

ASTM D257

|

|

Dielectricvoltage breakdown

|

32

|

KV

|

ASTM D149

|

|

Sleeves

|

Impact

|

15↑

|

N·m

|

ASTM G14

|

|

Free longitudinal contraction

|

25

|

%

|

ASTM D2732

|

|

Peel strength

|

To Primer Steel

|

140

|

N/cm

|

ASTM D1000

|

|

To PE Lining

|

100

|

N/cm

|

ASTM D1000

|

|

Cathodic disbondment

|

15

|

mm

|

ASTM G8

|

|

Water absorption

|

0.05↓

|

%

|

ASTM D570

|

|

Low Temp. flexibility

|

-32(-26)↑

|

ºC (ºF)

|

ASTM D2671-C

|

|

Max. Operation Temperature

|

65℃(149℉)

|

dimensions ordering info:

|

Adhesive Thickness

|

1.1mm(45mils)

|

1.3mm(50mils)

|

1.6mm(65mils)

|

Width:300mm~610mm(12"~24.4")

|

|

Backing Thickness

|

0.6mm(25mils)

|

0.9mm(36mils)

|

1.1mm(43mils)

|

|

Sleeves Thickness

|

1.7mm(70mils)

|

2.2mm(86mils)

|

2.7mm(108mils)

|

|

Installed sleeve Thickness

|

1.9mm(142mils)

|

2.4mm(94mils)

|

3.0mm(118mils)

|

Working drawing

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|