|

|

|

|

|

|

|

|

|

|

|

Cầu chì Bussmann

|

|

|

|

|

|

|

|

|

|

THIẾT BỊ CƠ KHÍ

|

|

|

|

|

|

|

|

|

|

Giá vàng

|

|

|

|

|

|

|

|

SẢN PHẨM CHÍNH

|

|

|

#939 Pipe Coating Repair Products

|

|

|

|

| |

|

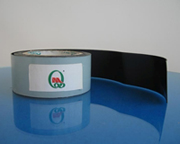

System Description The filler tapes are designed as an underlying filler materials prior to the application of coating systems.

Features (1) Excellent corrosion resistance. (2) Several colors available such as black, gray, green and red . (3) Conformable to irregular pipe (4) Compatible with general coating system.

PE repair patch : The product consists of an irradiated cross-linked polyolefin sheet coated with a heat activated adhesive and is designed specifically for sealing and protection of damaged pipeline coatings.

Advantages: -No special tools or equipment required -Excellent abrasion resistance-Inert to common acids,alkalis and solvents -Barrier to moisture and corrosion

Hot melt adhesive stick : Hot melt adhesive stick is composed of heat-activated adhesive with a stick form.It is used for repairing a small damage on the pipeline. It could be used as a filler material with PE repair patch.

Advantages: -Flexible -Excellent adhesion -Flows into hard-to-reach location -Excellent moisture resistance

Mastic filler : Mastic filler is used to fill larger voids and deep damaged coating prior to the application of PE repair patch.

Advantages: -Flexible under various field conditions -Conformable and moldable-Easy and simply application -Compatible with various coating system

Structure:

Physical Properties:

|

PE repair patch

|

Test

|

Method

|

Value

|

|

Tensile Strength of Backing

|

ASTM D638

|

22 MPa

|

|

Elongation at Break of Backing

|

ASTM D638

|

600%

|

|

Hardness, Shore D of Backing

|

ASTM D2240

|

52

|

|

Dielectric Strength of Backing

|

ASTM D149

|

35kV/mm

|

|

Adhesive Water absorption

|

ASTM D570

|

≤0.05%

|

|

Adhesive softening point

|

ASTM E28

|

125°C

|

|

Adhesive Lap shear @23°C

|

ASTM D1002

|

196psi

|

|

Peel strength of PE repair patch

|

ASTM D1000

|

60N/cm

|

|

Impact resistance of PE repair patch

|

DIN30672

|

20J

|

|

Hot melt adhesive stick

|

Impact resistance

|

DIN30672

|

22J

|

|

Dielectric Breakdown

|

ASTM D149

|

30kV/mm

|

|

Mastic filler

|

Elongation at Break

|

ASTM D638

|

600%

|

|

Hardness, Shore D

|

ASTM D2240

|

40

|

|

Low Temperature Flexibility

|

ASTM D2671

|

-40°C

|

|

Maximum operating temperature

|

-

|

85°C

|

Product selection method :

|

Selection Of Product

|

Max.Operating Temperature

|

Compatible Line Coating

|

Product

|

|

Small damage or

Scratch

|

114°F(80°C)

|

PE,PP,FBE,CTE

|

Only Hot melt adhesive stick or

with PE repair patch

|

|

Damage

|

PE,PP,FBE,CTE

|

Hot melt adhesive stick with PE repair patch or Mastic filler with PE repair patch

|

|

Large damage

|

Heat shrinkable sleeve is recommended

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|