| |

|

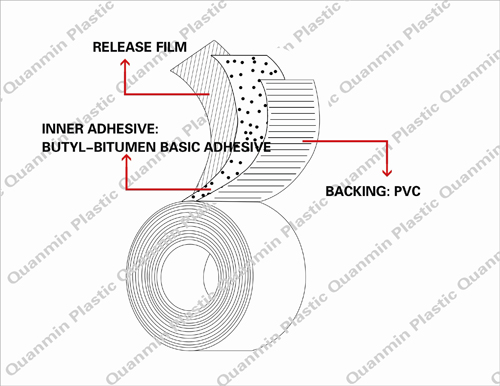

T600 PE butyl bitumen tape for corrosion protection of Oil, Gas, Petrochemical, Waste Water underground or overhead pipelines and waterproofing. The specification of the tape consists of three layers, Adhesive: Butyl rubber Bituminous Compound and Adhesion Promoting Resins. Film backing: Special blend of stabilized polyolefines. Interleaf: Anti-adhesive Film Treated with Silicone.

Features:

Heavy duty butyl bitumen compound adhesive.

Excellent adhesion to pipe and self.

Flexibility provides extra protection at vulnerable areas.

Excellent conformability and consistent uniform thickness.

Easily applied with no special equipment.

Compatible with common pipe coatings.

Excellent resistance to cathodic disbonding.

Resistant to UV.

Can be applied over a wide temperature range .

Good conformability and consistent uniform thickness.

Cold applied.

Structure:

Technical Data Sheet:

|

Physical Properties

|

Test Method

|

T660-45

|

T660-48

|

T660-55

|

T660-60

|

T660-65

|

|

Total Thickness

|

ASTM D 1000

|

1.15mm

|

1.20mm

|

1.40mm

|

1.50mm

|

1.65mm

|

|

Backing Thickness

|

ASTM D 1000

|

0.25mm

|

0.25mm

|

0.35mm

|

0.45mm

|

0.50mm

|

|

Adhesive Thickness

|

ASTM D 1000

|

0.90mm

|

0.95mm

|

1.05mm

|

1.05mm

|

1.15mm

|

|

Tensile Strength

|

ASTM D 1000

|

>60 N/cm

|

( >34.3 lbs/in )

|

|

Elongation

|

ASTM D 1000

|

>500%

|

( >500% )

|

|

Peel strength to Primed Steel at

|

|

|

At 23 ºC

|

ASTM D 1000

|

>80 N/cm

|

( >731oz/in )

|

|

At 50 ºC

|

ASTM D 1000

|

>10.5 N/cm

|

( >96 oz/in )

|

|

Adhesion to backing at

|

ASTM D 1000

|

>8.5 N/cm

|

( >77.7 oz/in )

|

|

Cathodic Disbondment

|

ASTM G 8

|

8.0mm

|

( 0.315 in radius )

|

|

Water Absorption Rate

|

ASTM D 570

|

<0.10%

|

( <0.10% )

|

|

Water Vapor

Transmission Rate

|

ASTM F 1249

|

<0.1 g/m2·24h

|

( <0.0064g/100sqin/24h )

|

|

Insulation Resistance

|

ASTM D 257

|

2.5×1015 ohm.cm

|

( 2.5 by 10 E 15 Mohm )

|

|

Dielectric Strength

|

ASTM D 149

|

28 KV

|

( 28 KV )

|

|

Impact Resistance

|

ASTM G 14

|

15 N·m

|

( 133 in·lbs )

|

|

Color

|

Black ,White,yellow or other

|

|

Tape width in inches

|

50mm(2"),101mm(4"),152mm(6"),228mm(9"),305mm(12"),457mm(18"),

610mm(24"),750mm(29.5"),800mm(31.5"),1000mm(39")

|

|

Tape roll length in feet

|

15m(50ft),25m(82ft),30m(98ft),50m(164ft),61m(200ft),100m(328ft),122m(400ft)

|

|

Core size

|

38mm(1.5"),76mm(3") core of paper or hard plastic

|

|

Application Temperature

|

-34 ºC to +120 ºC

|

( -29 ºF to 120 ºF )

|

|

Operating Temperature

|

+120 ºC

|

( 248 ºF )

|

|