| |

|

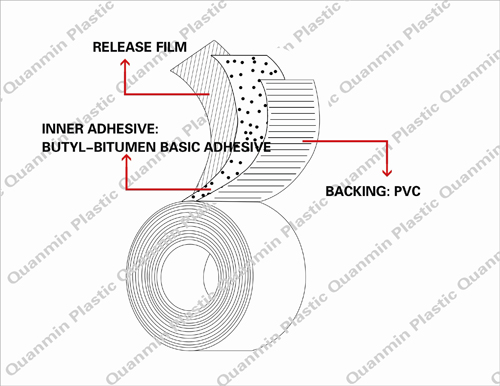

PVC anticorrosive tape is "All Weather" pipe protection tape. The tape is composed of PVC plastic backing and high adhesion synthetic rubber adhesive. The adhesive layer is composed of butyl rubber(BR) or butyl rubber base modified bitumen compound(BC). The PVC plastic backing has excellent electrical insulation and chemical resistance. The synthetic adhesive has excellent anti-aging, seal ability effect. So it is always used for corrosion protection for metal piping systems above and below ground.

PVC anticorrosive tape is easy to apply with no special tools or equipment. Being highly flexible, it is suitable for work in low temperature and for work on joint part or flexural area. It provides positive protection against abrasion and corrosive action for steel pipe, fittings or electrical conduit systems.

Features:

Offers superior durability and corrosion resistance.

Consists of flexible film and thick adhesive. Adheres well to joints and curved part. Provides superior sealing and cushioning. For anticorrosion and protection of various types of pipelines.

Structure:

Standard Ordering options:

Test Data sheet

|

Physical

Properties

|

Test

Method

|

T540BR-16

|

T550BR-20

|

T5150BC-60

|

T5165BC-65

|

|

Metric

|

English

|

Metric

|

English

|

Metric

|

English

|

Metric

|

English

|

|

Total

Thickness

|

ASTM D

1000

|

0.41mm

|

16mils

|

0.51mm

|

20mils

|

1.50mm

|

59mils

|

1.65mm

|

65mils

|

|

Backing

Thickness

|

ASTM D

1000

|

0.28mm

|

11mils

|

0.31mm

|

12mils

|

0.50mm

|

20mils

|

0.75mm

|

30mils

|

|

Adhesive

Thickness

|

ASTM D

1000

|

0.13mm

|

5mils

|

0.20mm

|

8mils

|

1.00mm

|

39mils

|

0.90mm

|

35mils

|

|

Elongation

|

ASTM D

1000

|

225%

|

225%

|

250%

|

250%

|

270%

|

270%

|

300%

|

300%

|

|

Tensile

Strength

|

ASTM D

1000

|

98 N/25mm

|

22

lbs/in

|

148

N/25mm

|

33.3

lbs/in

|

372 N/25mm

|

83.6

lbs/in

|

392 N/25mm

|

88.1

lbs/in

|

|

Peel strength to Primed Pipe

|

ASTM D

1000

|

59

N/25mm

|

212.4

oz/in

|

61 N/25mm

|

219.6

oz/in

|

88 N/25mm

|

316.8 oz/in

|

88 N/25mm

|

316.8

oz/in

|

|

Adhension to

Self

|

ASTM D

1000

|

13 N/25mm

|

46.8

oz/in

|

13

N/25mm

|

46.8

oz/in

|

78

N/25mm

|

280.8

oz/in

|

78

N/25mm

|

280.8

oz/in

|

|

Impact Resistance

|

ASTMG 14

|

11 Nm

|

97.36

in-lbs

|

11 Nm

|

97.36

in-lbs

|

15 Nm

|

132.76 in-lbs

|

15 Nm

|

132.76 in-lbs

|

|

Tear Strength

|

ASTM D

1004

|

40 N

|

8.99 lbs

|

43 N

|

9.67 lbs

|

50 N

|

11.24 lbs

|

51 N

|

11.47 lbs

|

|

Dielectric

Strength

|

ASTM D149

|

30 KV

|

30 KV

|

35 KV

|

35 KV

|

38 KV

|

38 KV

|

40 KV

|

40 KV

|

|

Insulation

Resistance

|

ASTM D

257

|

108

Mohm

|

10E 8

Mohm

|

1010

Mohm

|

10E10

Mohm

|

1012

Mohm

|

10E12

Mohm

|

1012

Mohm

|

10E12

Mohm

|

|

Water Vapor

Transmission

Rate (24h)

|

ASTM E96

|

0.1

g/m2·24h

|

0.0065

g/100sqin

/24h

|

0.1 g/m2·24h

|

0.0065g

/100sqin

/24h

|

0.2

g/m2·24h

|

0.013

g/100sqin

/24h

|

0.2

g/m2·24h

|

0.013

g/100sq

in/24h

|

|

Water

Absorption

|

ASTM D

570

|

0.08%

|

0.08%

|

0.08%

|

0.08%

|

0.10%

|

0.10%

|

0.10%

|

0.10%

|

|

Application

Temperature

|

-34 ºC to +85 ºC ( -29 ºF to 185 ºF )

|

|

Operating

Temperature

|

+85 ºC ( 185 ºF )

|

|

Color

|

Black, White, Yellow, Blue

|

|

Tape width

in inches

|

25mm(1"),50mm(2"),75mm(3"),101mm(4"),152mm(6"),228mm(9"),305mm(12"),457mm(18"),

610mm(24"),750mm(29.5")

|

|

Tape roll

length in

feet

|

10m(33ft),15m(50ft),25m(82ft),30m(98ft),50m(164ft),61m(200ft),100m(328ft),122m(400ft),

183m(600ft),244m(800ft)

|

|

Core size

|

30mm(1.2"),38mm(1.5"), 76mm(3") core of paper or hard plastic

|

|